CS Soft Energy Analyzer

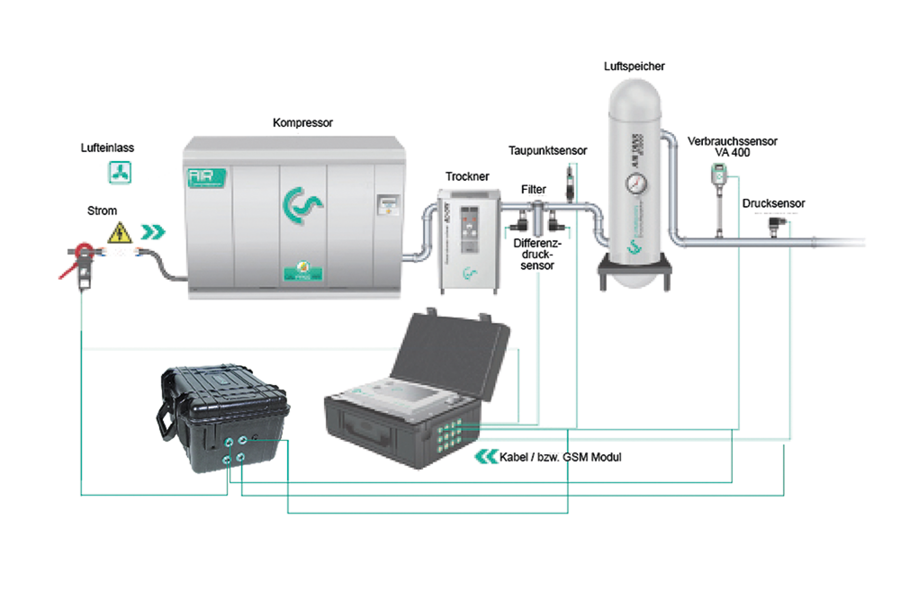

- Used for compressor analysis (current/power measurement)

- System analysis (current measurement and actual flow measurement)

- Leakage calculation

Compressor Analysis (Consumption and Power Measurement)

The energy consumption of each compressor is measured using an ammeter clamp. The amount of compressed air produced is calculated by the software based on the compressor's technical specifications, which need to be entered into the system by the operator. The following parameters are then calculated: energy consumption in kWh, load/unload, stop time, compressor load %, number of load/unload cycles.

System Analysis (Flow Measurement and Actual Flow Measurement)

The system analysis serves the same function as compressor analysis but additionally allows for comparing the energy produced with the amount of air used through the flow sensor. With "actual flow measurement," we can identify leaks and, consequently, the relationship between generation costs and total losses in € or %.

Leakage Calculation

Leakage calculation occurs during periods when the production plant is idle (nights, weekends, holidays) using a flow sensor. This involves comparing the compressor's electrical consumption time against the air supplied at a constant pressure. According to statistics and experience, even if production operates around the clock, there's usually a brief period when all consumption is disconnected. This moment helps detect leaks in the installation and allocate their costs in €.